With about 29,000 year-round residents, Ithaca is remarkable for the diversity and erudition of its population, its commitment to the arts and civic life, and its natural beauty. AAP’s physical campus footprint includes The Foundry, Milstein Hall, Rand Hall, Sibley Hall, and Tjaden Hall.

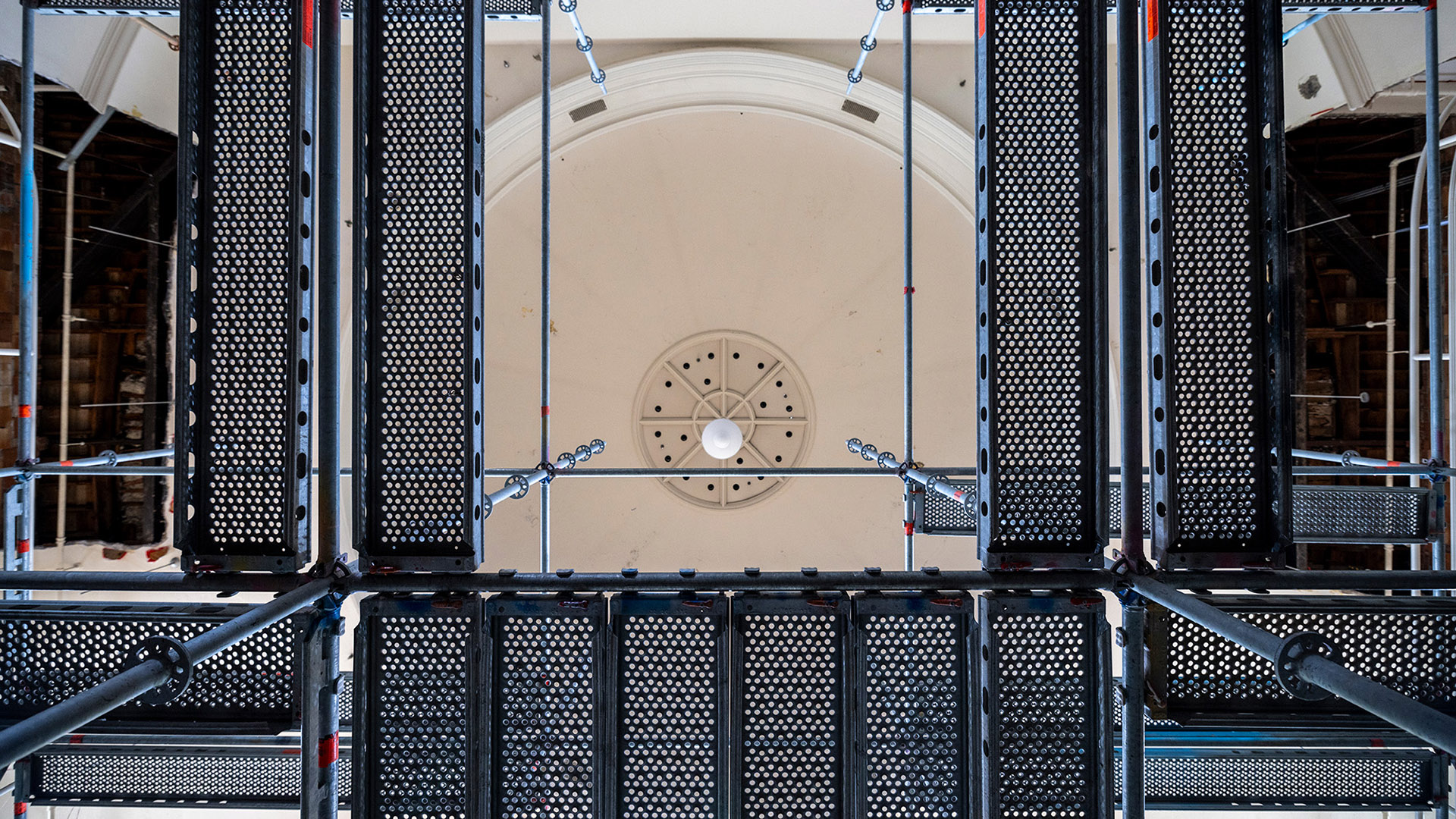

Sibley Dome

New and Renewed

The renovation of Sibley Dome began in June 2024 and is currently underway. The project’s anticipated completion date is spring 2026. When finished, the dome will house new and updated teaching, learning, and gathering spaces while preserving historical details.

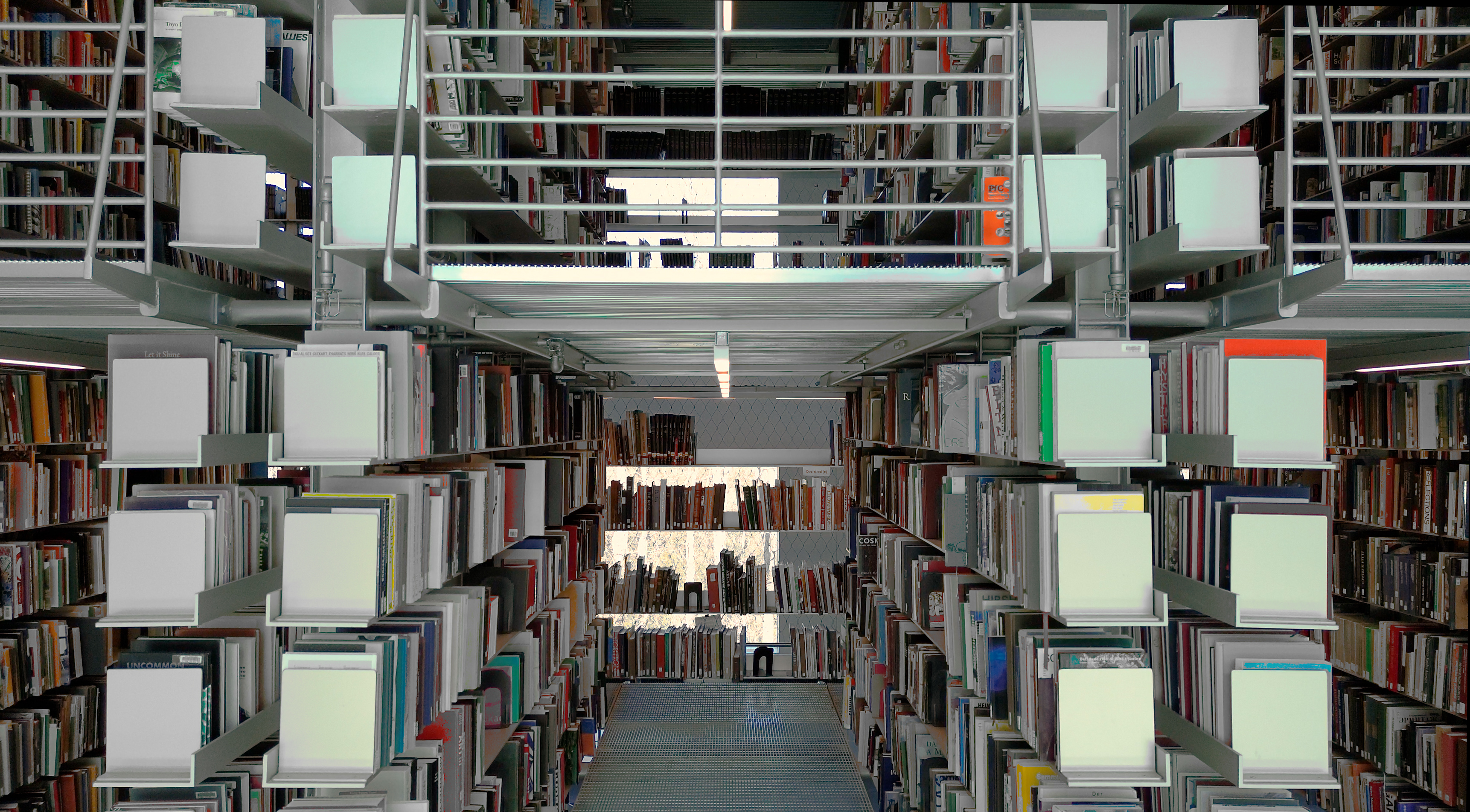

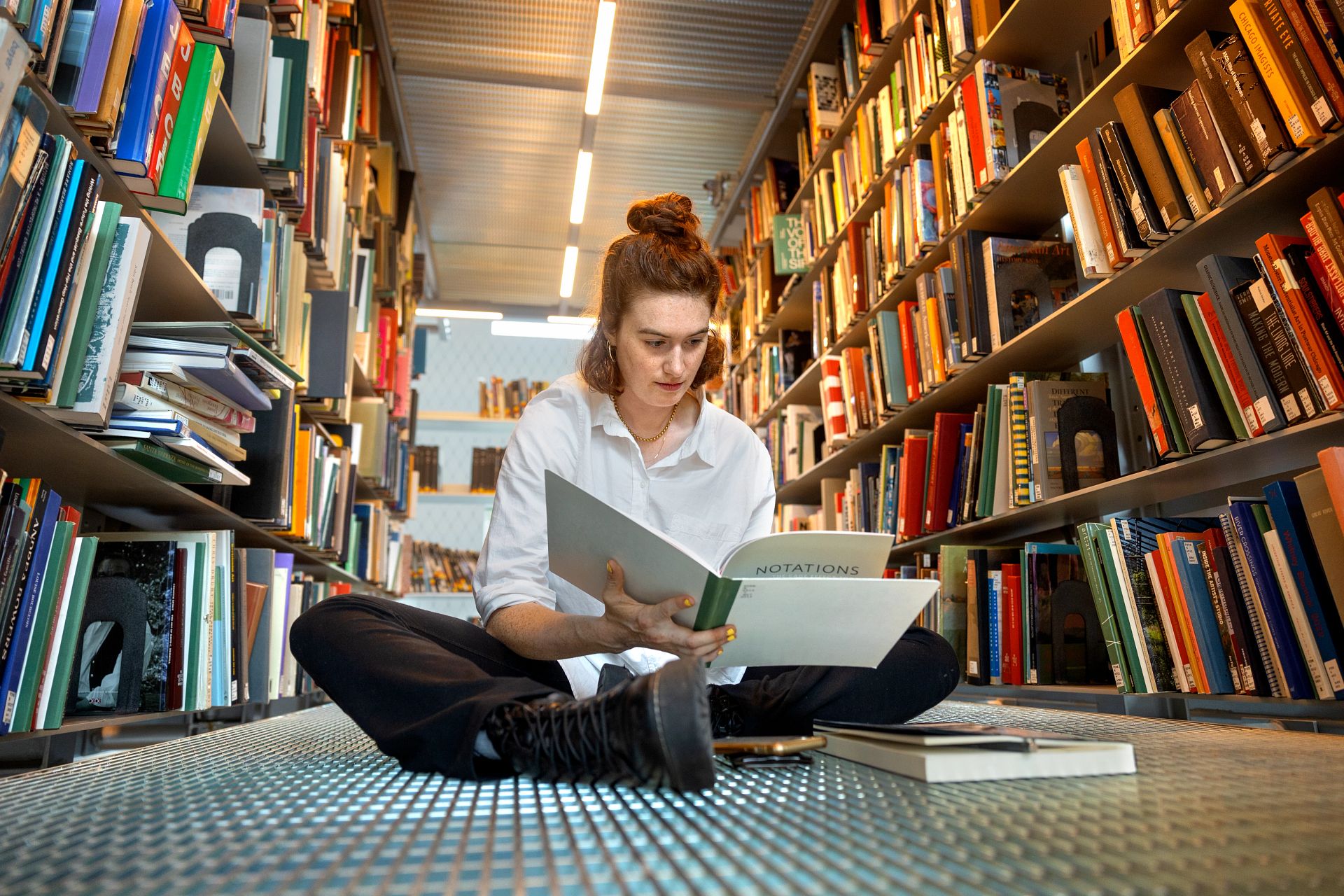

Mui Ho Fine Arts Library

A Landmark Library

Thanks to a generous gift from AAP alumna Mui Ho (B.Arch. ’66), the Mui Ho Fine Arts Library in Rand Hall welcomes patrons to one of the country’s most extensive circulating collections of fine arts and design materials. Opened in 2019, the library was designed by architect Wolfgang Tschapeller (M.Arch. ’87), whose goal for the project was a 21st-century interpretation of the grand reading rooms associated with great research collections.

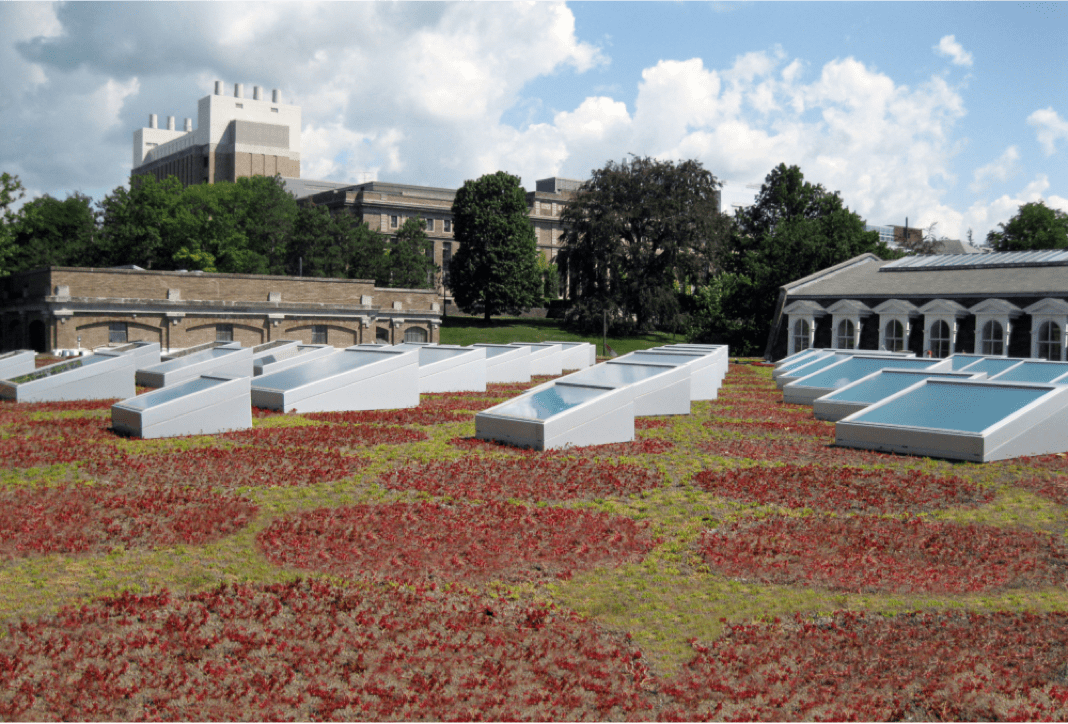

Milstein Hall

Built to Inspire

Designed by Rem Koolhaas and OMA, Milstein Hall is home to the college’s architecture programs and is named in honor of philanthropist Paul Milstein. The building opened in 2011 and includes the 25,000-square-foot L. P. Kwee Studios, the Bibliowicz Family Gallery, Milstein Hall Dome, and the Howard and Abby Milstein Auditorium and Boardroom.

Milstein Hall weaves contemporary architecture through the college’s historic buildings, creating a dynamic landscape and a vibrant central meeting place that lends itself to collaboration.

Other Landmarks

Sibley Hall

Divided into three parts — the west wing, the dome, and the east wing — Sibley Hall is home to the Department of City and Regional Planning, several of the college’s administrative offices, the John Hartell Gallery, Frances Shloss Studio, classrooms and exhibition spaces, shared work spaces, and the beloved Green Dragon Cafe.

Tjaden Hall

Olive Tjaden Hall houses the Department of Art, the Olive Tjaden Gallery, the Experimental Gallery, numerous classrooms and art studios, various labs, and a darkroom. The building is named after Olive Tjaden Van Sickle (1925), a pioneering woman architect and artist whose substantial gift made the 1998 renovation of the building possible.

The Foundry

The Foundry, a protected historic building on the edge of the Cascadilla Gorge, was completely renovated in 2024 and comprises the M.F.A. in Creative Arts student studios as well as the college’s newly named Jack Squier Sculpture Studio.

Rand Hall

In addition to the impressive Mui Ho Fine Arts Library, Rand Hall houses Cornell AAP’s state-of-the-art fabrication facilities, including the Autodesk Design and Make Space, which was named and supported thanks to a 2025 gift from Autodesk.

Cornell University’s Ithaca Campus

Cornell’s main campus provides a wide variety of opportunities and unique offerings across a dynamic range of departments and subject areas. Students are encouraged to explore all that the university has to offer during their time in Ithaca.

Learn more about the university’s Ithaca campus.

Beyond Campus

Located at the south end of Cayuga Lake — the largest of the Finger Lakes — Ithaca boasts unsurpassed natural beauty in its gorges, state parks, and waterfront.

Collegetown and the Ithaca Commons are a short walk from campus, offering a city atmosphere with shopping, restaurants, cultural activities, and nightlife. Between urban life and alluring countryside, Ithaca has something for everyone to see and do.

Learn more at Visit Ithaca.