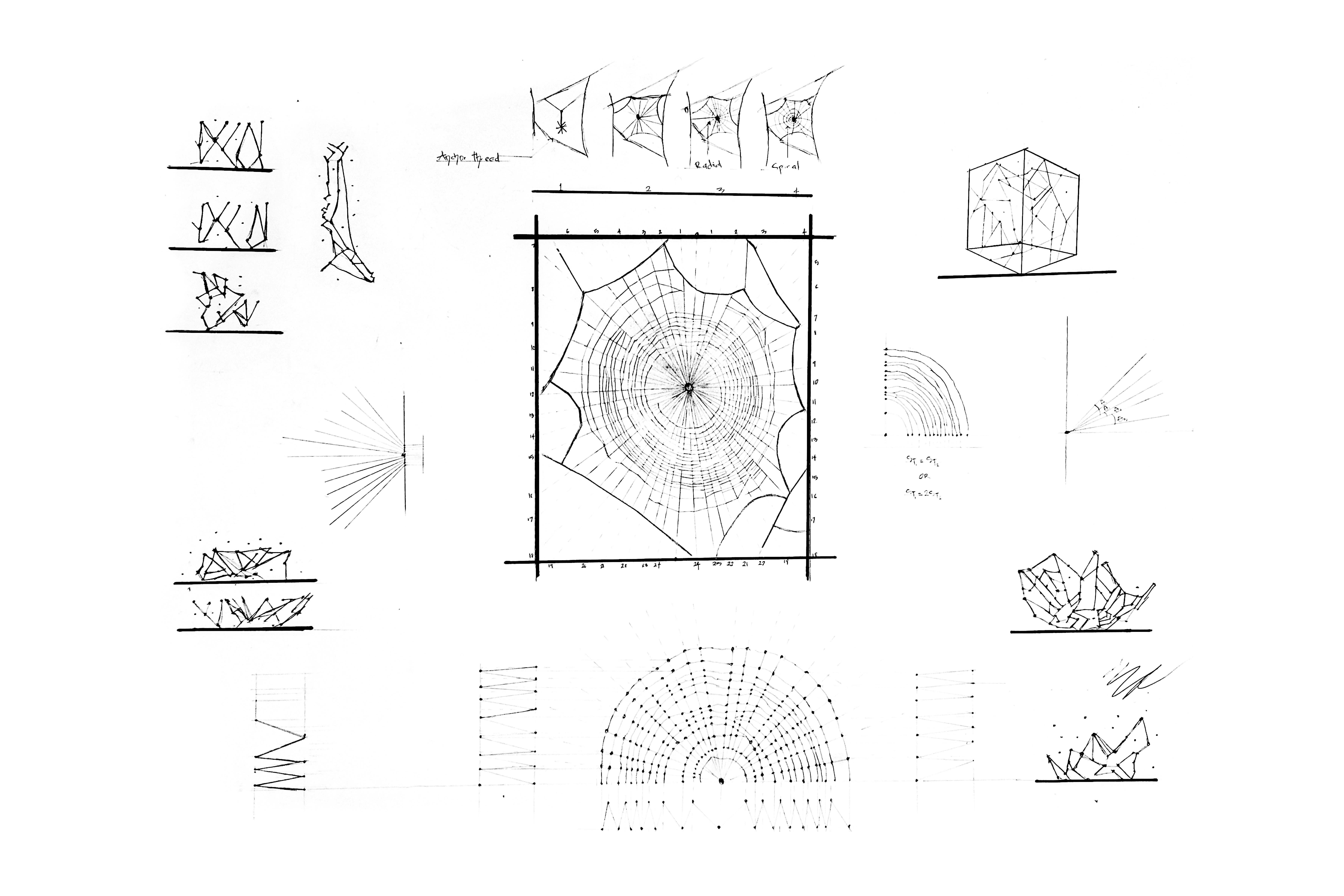

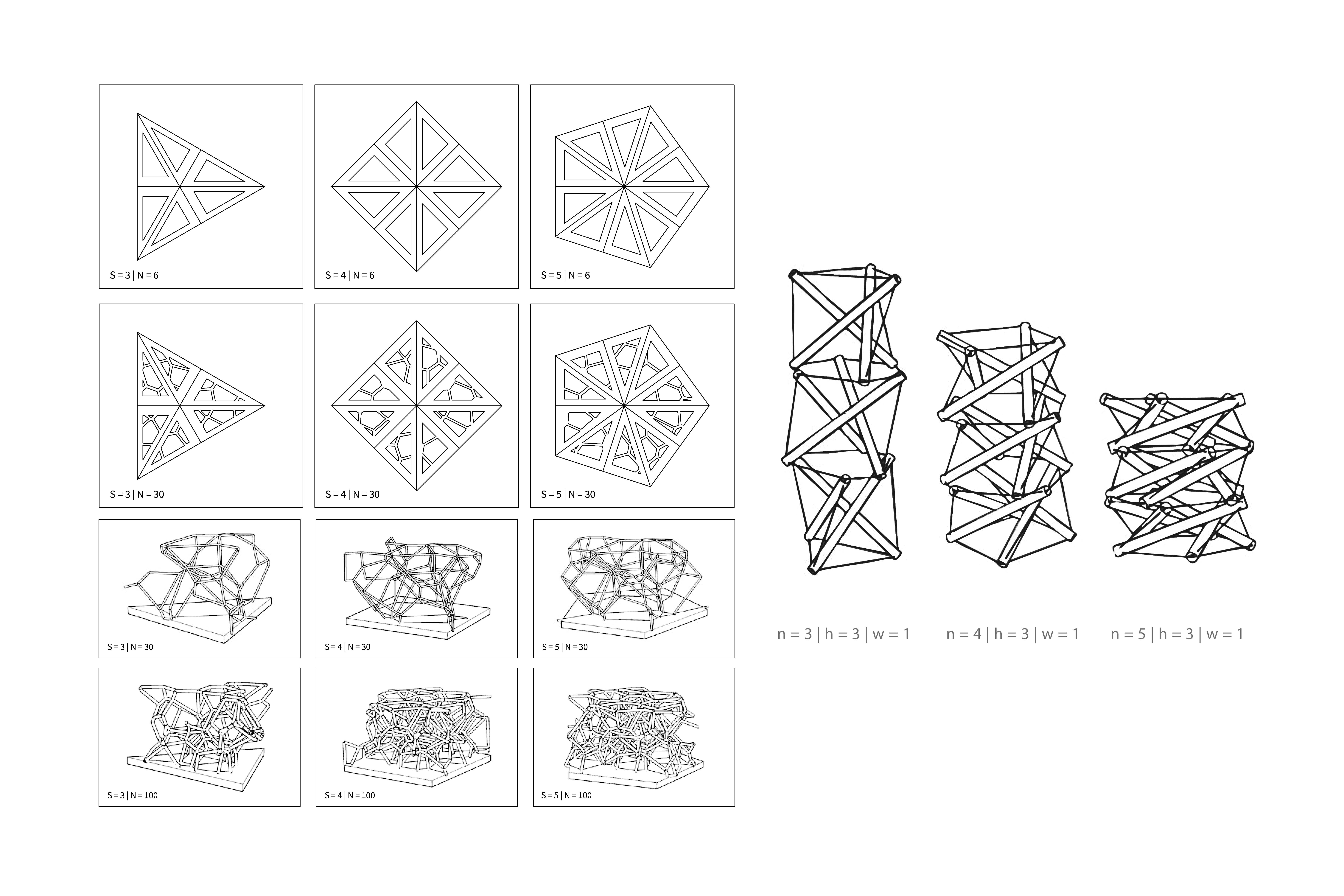

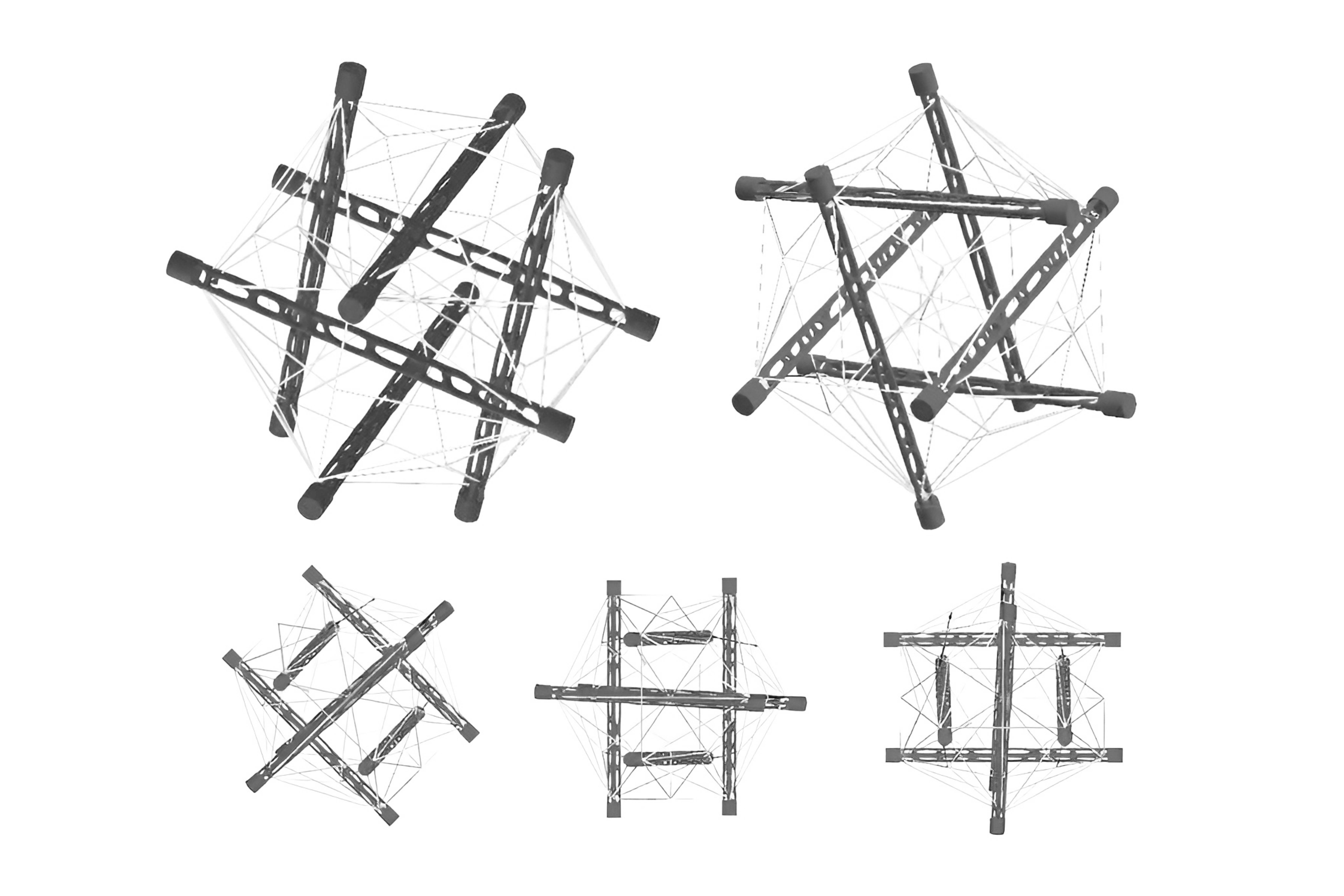

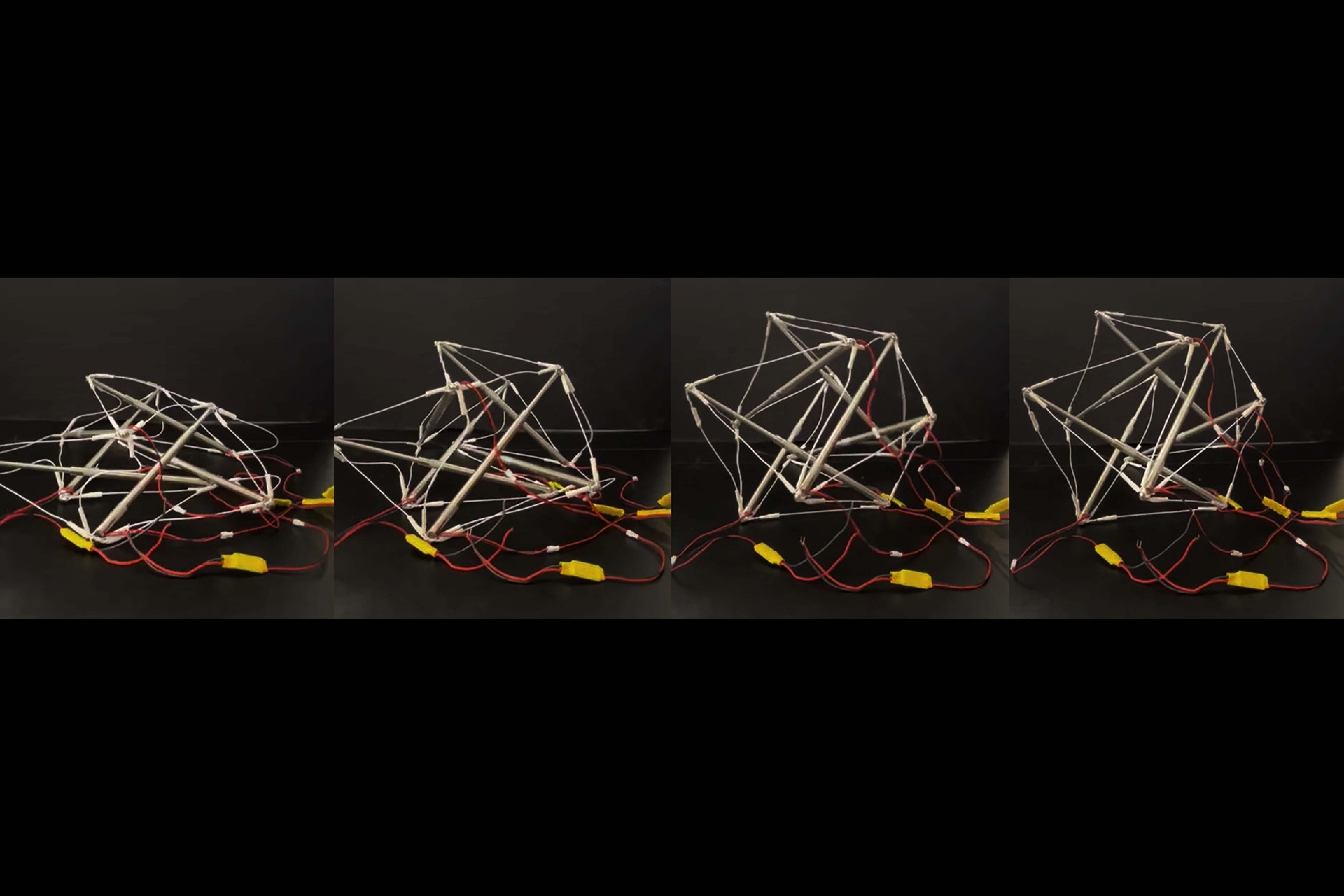

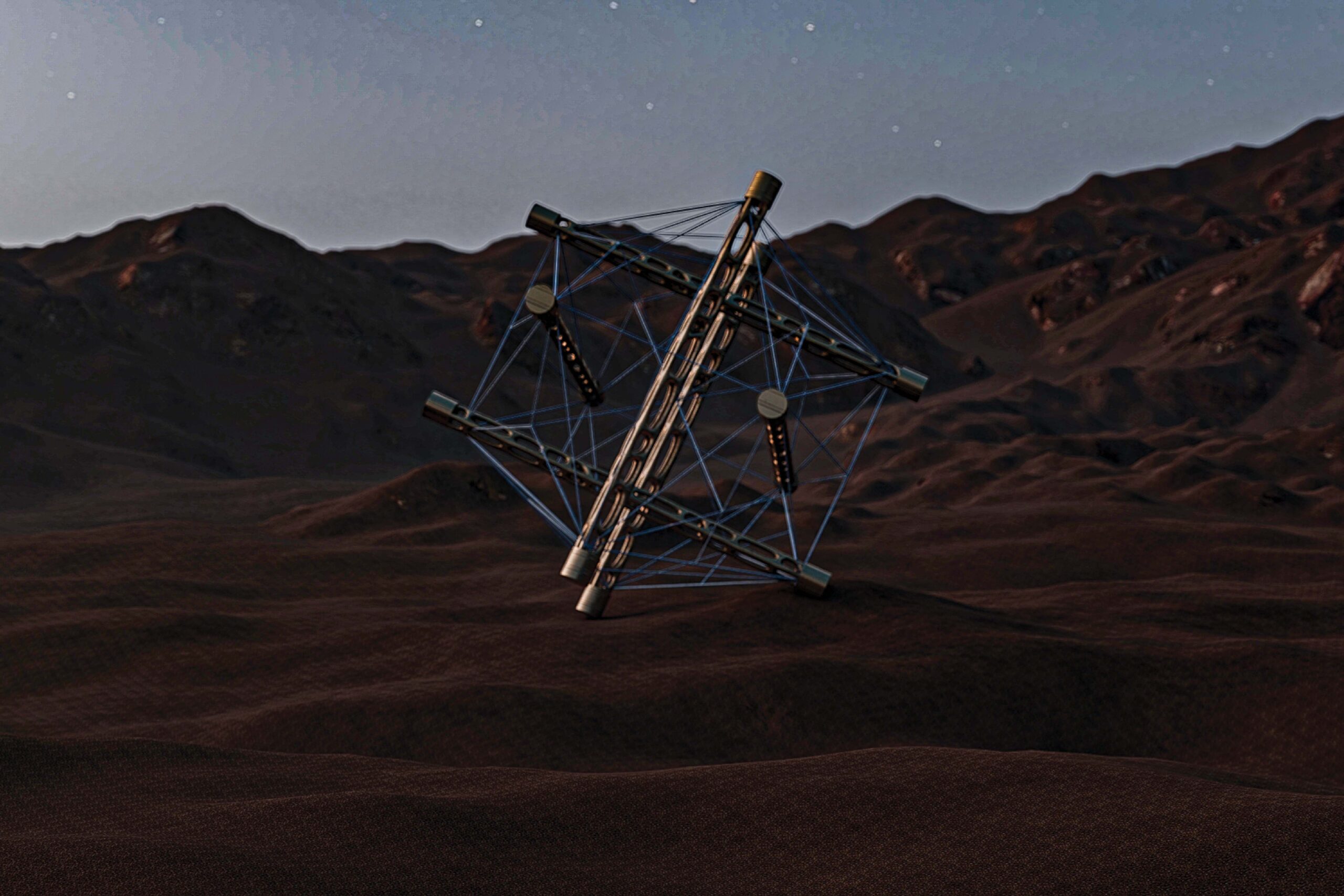

By analyzing tension distribution in spider web geometries, this research redesigns the tensile networks in tensegrity structures, ensuring that localized failures do not propagate and cause global collapse. The study integrates digital simulations, material explorations, optimization processes, and physical prototyping to develop and evaluate various configurations. The Web Tensegrity Structure is designed for Mars exploration, blending resilience with locomotion to enhance structural redundancy, failure resistance, and mobility—critical advantages for extraterrestrial missions.

Findings from computational simulations and physical experiments demonstrate that incorporating spider web-inspired tension networks significantly improves force distribution and structural integrity, effectively mitigating catastrophic failure when individual components are compromised. This biomimetic approach not only strengthens tensegrity systems but also expands their applicability in deployable structures, robotics, and aerospace engineering.

This work challenges conventional tensegrity paradigms and introduces a novel adaptive stability framework, paving the way for more durable, fail-safe, and multifunctional tensegrity structures.

Medium of physical object:

3D printed models (PLA filament), purchased struts, and hand-assembled cables.